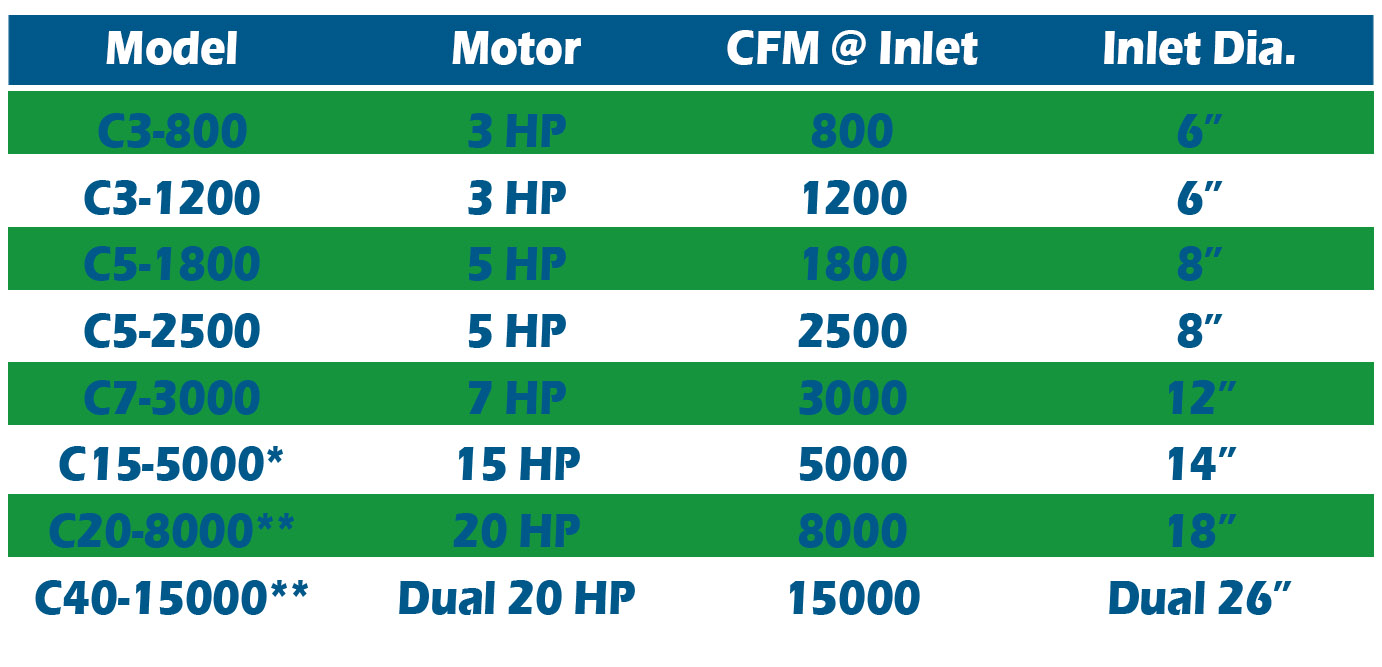

AT Industrial Wet Dust Collector Systems

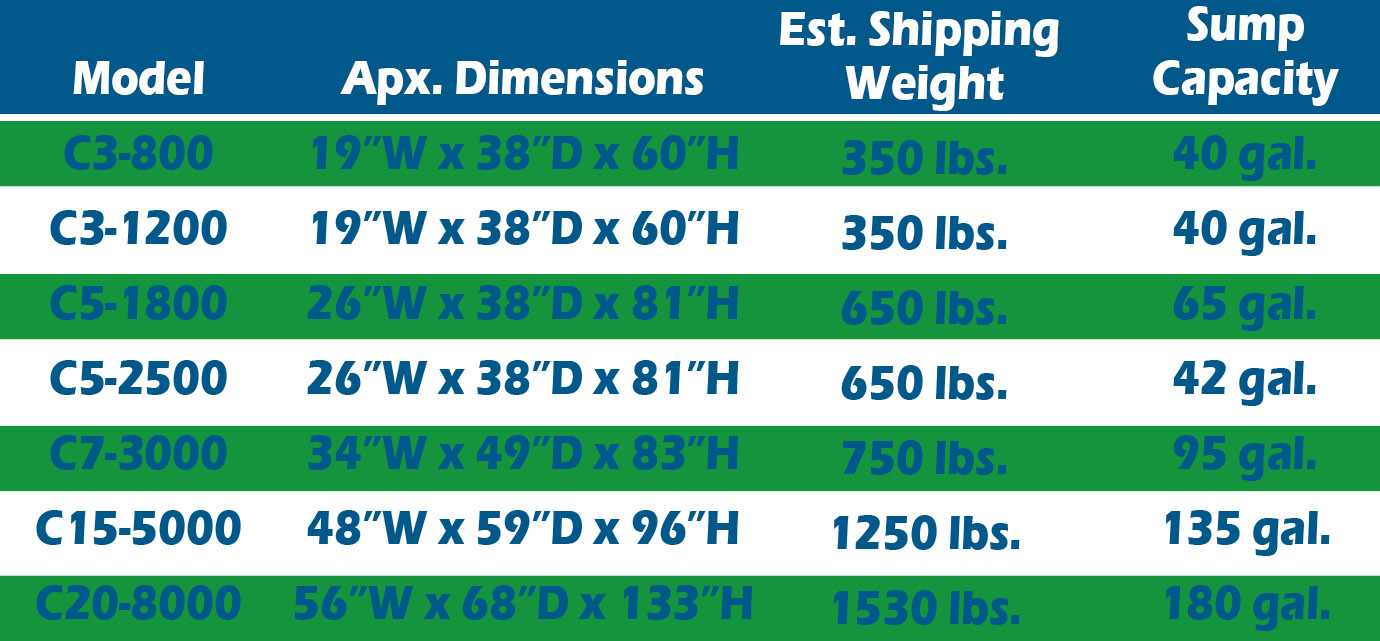

C3-800

C3-1200

C5-2500

C7-3000

C15-5000

C20-8000

C40-15000

Standard Specifications:

CABINET – 304 seam welded stainless steel, US certified

MAINTENANCE DOOR – easily removed for maintenance & cleaning

MOTOR – T.E.F.C. 208-230/460 volt, 3-phase, 60 Hz (other voltages also available)

INLET – CFM tested at the inlet without duct attached

ELECTRICAL CONTROL – dial type starter with thermal overloads

IMPELLER – standard, precision balanced, direct coupled to the motor for maximum

CFM with minimum vibration (also stainless steel)

FILTRATION – a system of internal baffles separates and removes dust particles from

the water.

HOOD – easily accessible front facing latches and foam sound suppression panels on

all four inner walls for maximum noise reduction

AUTOMATIC WATER LEVEL CONTROL – allows for user’s connection to a water

supply line for automatic water fill

CLEANING TOOL – made of stainless steel and provided for the easy removal of

grinding dust and sludge from the bottom of the collector

Options:

Custom Table Sizes

OSHA/NFPA Compliant Electrical Panel

Pneumatic & Electric Power Outlets

Wheel grinding fixture

Removable Deflector Walls

Options:

- NFPA/OSHA Compliant electrical pacakge

- Starts collector when process machinery is turned on

- Monitors water level to ensure proper CFM production

- Shuts down processing equipment and wet collector when water level is too low or too high.

- Extended sump, stainless steel cover and flange

- Moves inlet from vertical to horizontal position

- Eliminates 45° & 90° elbow off the back of the unity

- Allows straight duct to attach to the flange located on top of the sump cover

- Sludge Vac

- Vacuums sludge and water out of wet collector sump and through a filter. Flip a switch and filtered water is returned to the sump.

- Lightweight polypropylene front access door

- Silencer

- Stand

- Legs

- Overflow Pan

- Explosion Proof Motor

- Custom Color

- Private Label

OSHA/NFPA Compliant Electrical Package provides start from a closed contact at the process machinery. Interrupts the circuit if the water level is too high or low. Ultrasonic water level sensor and valve, hazardous gas exhaust vent, PLC, time delay, warning light, alarm and NEMA 12 enclosure. Every machine is tested and run before leaving our shop to ensure correct CFM production and water doesn’t migrate up and out of the machine. When correct water level is maintained our wet dust collectors don’t weep, seep or leak.

Click here to see the Performance Curves for the AT Industrial Wet Dust Collector.

** C20-8000 & C40-15000 and larger come standard with the upgraded OSHA/NFPA electrical package.

Contact AT Industrial Products Today

We enjoy partnering with our distributors and our vendors. Building loyal partnerships creates an environment of trust that is collaborative, supportive, productive and profitable. We look forward to hearing from you!